Cransford Polythene Ltd. was formed in November 1989 in a 3000 square feet factory unit in the village of Cransford, hence the name. At that time the company was a converter only of polythene bags and sheets. In 1990 we moved into film extrusion.

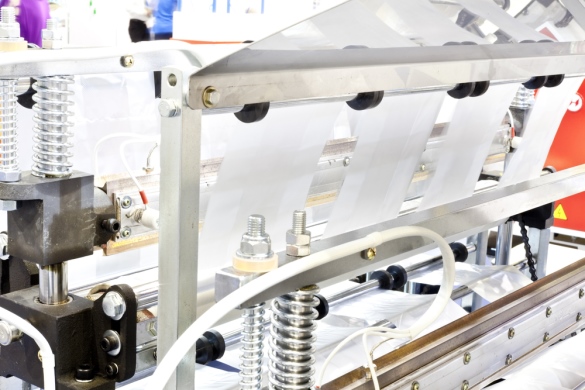

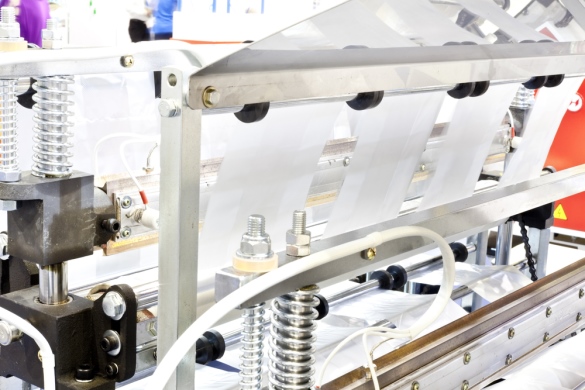

In 1991 due to increasing demand, it was necessary to change to 24 hour working. This created noise problems for nearby housing and we then moved the whole business to its current location, Crabbes Farm, Parham, Suffolk. With no noise restrictions due to its remote locality the Company continued to grow, now filling approximately 17000 square feet of factory and warehousing. We now have 4 extrusion lines, two colour and three colour flexographic printers and five bag making machines. Recent investments have included a bag machine and automated box sealing machine.

Originally we were making nearly all refuse sacks, however over the past 10 years most of this market has fallen to imported bags, originally, lower cost base European countries such as Italy and Spain, then Eastern European countries such as Latvia and more recently India and now China. This has led our sales effort to concentrate on bespoke, made to order sizes and thicknesses and also very small minimum quantities as we feel this market is currently import proof. We therefore can offer very competitive prices.

Our extrusion lines can make lay flat tubing from 4" up to 60", and up to 63" with a gusset and our polythene conversion machines can make bags or sheets up to 1.3 metres wide and 3 metres long. We can punch 6mm holes or rows of pin pricks for ventilation. We can print up to three colours for good point of sale display packaging and an inline printer for inexpensive warning panel bags.

Products are all made to the ISO9001:2000 quality standard with all the associated written quality procedures to ensure that every effort is made to make all products as required by the customer.